As an operator of smelters around the globe, we understand firsthand the specific requirements needed to ensure the best possible smelter operation.

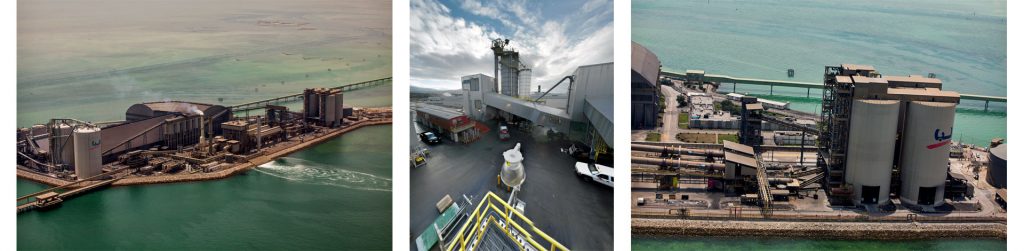

BATH PROCESS PLANT

Our technology significantly improves pot operation and current efficiency while overcoming the well‑known challenges associated with the conventional process.

Autogenous crushing with gravity discharge

Our crushing process is based on a high capacity autogenous crusher with gravity discharge. The crusher is custom designed to meet your exact bath materials requirements.

Low energy consumption, low maintenance and long lifetime are among the benefits generated by our core bath processing equipment.

Bath material mixing

The various fractions are mixed in the quantities required to maintain a given grain size distribution.

Our technology in this field covers the entire bath cycle. It ensures that a consistent bath materials mixture is returned to the pot.

REEL Alesa bath process plants provide you with the most consistent bath quality for a reliable pot operation.

CARBON RECYCLING PLANT

High efficiency and capacity

Our handling and crushing processes leverage high efficiency and capacity systems, ensuring optimal plant availability and performance. Each system is custom designed to meet your material requirements. Safe operation, low energy consumption and maintenance as well as a long lifetime are among the benefits of our core materials handling technologies.

Our integrated approach to the management of spent carbon material encompasses all process streams. It enables full recovery for either reprocessing and/or disposal depending upon your requirements.